( A first here at MD, as we blog while brewing. I'm doing an all grain brew which really needs to be babied for an hour or so).

Back to the wheel/axle/bearing discussion today. In the last week or so on a variety of forums there have been a few ideas tossed around. In no particular order here they are.

1) Stick with the status quo. Well, actually this hasn't been proposed but is certainly the cheapest and easiest option. The main drawback is that with out some cunning jiggery-pokery behind the scenes the various outside bits will be just too wide. Not a big problem (well less of a problem) for the modern image guys, but the rest of us could have problems.

2) Wheels with shorter axles. On the face of it quite the obvious solution. However the British wheel suppliers won't deal in anything less than 1000 axles ( that's a scary thing to see in an e-mail). Not quite what we want just for a test.

3) Shortened axles. A novel suggestion to cut the axle in 1/2, remove a couple of mm and rejoin with a piece of brass tube. Maybe not as daft as it sounds

4)Inside/outside bearings. I had a crack at this on my aborted Ja tender, and the inside bearings worked fine. They didn't quite run as well as the pinpoint variety. It would solve the whole wheel/solebar relationship by ignoring it completely. The other option here is to have plain flat-ended axles running in tube bearings. This was used by the 9mm crowd 20 odd years ago, as heavy wagons in normal pinpoints would splay the solebars. Again I think it would not quite run as well as pinpoints, and the engineering involved might be a bit harder (only my opinion).

What does everyone else think. An opnion from the manufacturer on what he would like to see could prove useful (must think of the market and all). looking at the Trackgang models I have, they could stand a 12.5mm axle I think

One option not commented on is the subject of a phone call received last night by 2 gentlemen stuck in traffic on the way to a BBQ on the Kapiti coast. Its content's suggest either some warmups and qualifiers had been indulged in, or the carbon monoxide levers in the car need investigating...

Wednesday, September 30, 2009

Tuesday, September 29, 2009

Sorry but its overdue.

Its been well over a week since the last guards van post, so its well overdue for another one. I've got one of the vans on its 'feet' and have done a bit of painting. This van is going to be a plough van so will be a bit more paint worn. therefor its just got one layer of paint which is giving it a nice pinkish tinge.

this was a bit difficult to get to run OK as for some odd reason the wheels would lock up running one way when pushed along the track, but this little problem could not be replicated when it was upside down being investigated. I therefore was forced to cut out a bit more plastic underneath to accommodate the wheels beyond what I had already removed. no idea what was going on but it has worked.

this was a bit difficult to get to run OK as for some odd reason the wheels would lock up running one way when pushed along the track, but this little problem could not be replicated when it was upside down being investigated. I therefore was forced to cut out a bit more plastic underneath to accommodate the wheels beyond what I had already removed. no idea what was going on but it has worked.

Monday, September 28, 2009

More not guards van stuff

Just a quick job tonight, as I knocked up a chassis for my Z wagon from 2mm plasticard. It was cut to size, and then the holes were drilled for the bolts in the bogies. I then sorted out the various washers and nut's required.

To accommodate the bolts running up into the body (that was full of MDF) I had to drill out some holes carefully without going through the roof. These were about 5mm in diameter. I then just dropped the top on to check I had it right.

It will have to wait a couple of weeks till I can get some angle brass for the underframe.

To accommodate the bolts running up into the body (that was full of MDF) I had to drill out some holes carefully without going through the roof. These were about 5mm in diameter. I then just dropped the top on to check I had it right.

It will have to wait a couple of weeks till I can get some angle brass for the underframe.

Sunday, September 27, 2009

Carry on...

To drag myself away from building more guards vans (I have a list with 15 on it of 10 different types now) I am finally attempting a model that I have always wanted to do, but never had a courage to face; the 47' carriage.

These are quite frightening modeling wise as they have a stack of horizontal and vertical bits that all have to line up or it looks silly. Fortunately now that I can get evergreen styrene online its a bit easier.

I started with a sheet of N scale siding (0.5mm thick), and cut a piece to size off the plan (13mm deep by whatever long) taking into account that the ends were going to be full width and the sides slightly shorter when it was all assembled. I then lined up my piece of plasticard and used a pencil (one of those tech drawing thingie one) and marked out where the windows were. A pencil line was then drawn across the whole sheet where the bottom of the window was to be, and the lines extended from the top to the line. Cutting the waste away started with cutting the bottoms of the windows (not all the way through) and then using the pre-scribed lines to guide the vertical cuts (which were right through). The waste bits were then removed by snapping them out of the frame. (the picture shows my first attemp in which I screwed up one of the window widths and had to do it all again).

The second layer was made from 0.5mm plain plasticard. Again this was 13mm deep and the same length as the top piece. I marked on the sheet where the bottom of the windows were (the glass bit) and then scribed this all the way across without cutting right through. The 2 pieces of plastic were then laminated together and left to dry. I then marked out the edges of the windows with a pencil and cut them out, cutting the verticals and then snapping the waste pieces out. Any of these lines that were not square got a bit of filing and knife work to tidy them up. I also discovered that one of my files was the correct width to clean the window frames up which made the job a wee bit easier. The bottom beading on the window frames was made by gluing a pieces of evergreen microstrip across at the right height and then removing the bits between windows. Its not ideal but they do all line up which is a bit more important (I'll have to paint it now to check it doesn't look silly and the blemishes are not too deep).

Finally I tacked the bits above the windows. This was cut in one piece from a piece of 1mm plasticard. I was not sure how I was going to do all the raised beading on the edges, and it was a pleasant surprise to discover that the burrs raised from cutting the plastic sheet were just about right. The beading running down the center of this bit was done again using microstrip.

So, here's how it looks after a night being left to dry (pressed under a piece of glass so that it would not warp)

These are quite frightening modeling wise as they have a stack of horizontal and vertical bits that all have to line up or it looks silly. Fortunately now that I can get evergreen styrene online its a bit easier.

I started with a sheet of N scale siding (0.5mm thick), and cut a piece to size off the plan (13mm deep by whatever long) taking into account that the ends were going to be full width and the sides slightly shorter when it was all assembled. I then lined up my piece of plasticard and used a pencil (one of those tech drawing thingie one) and marked out where the windows were. A pencil line was then drawn across the whole sheet where the bottom of the window was to be, and the lines extended from the top to the line. Cutting the waste away started with cutting the bottoms of the windows (not all the way through) and then using the pre-scribed lines to guide the vertical cuts (which were right through). The waste bits were then removed by snapping them out of the frame. (the picture shows my first attemp in which I screwed up one of the window widths and had to do it all again).

The second layer was made from 0.5mm plain plasticard. Again this was 13mm deep and the same length as the top piece. I marked on the sheet where the bottom of the windows were (the glass bit) and then scribed this all the way across without cutting right through. The 2 pieces of plastic were then laminated together and left to dry. I then marked out the edges of the windows with a pencil and cut them out, cutting the verticals and then snapping the waste pieces out. Any of these lines that were not square got a bit of filing and knife work to tidy them up. I also discovered that one of my files was the correct width to clean the window frames up which made the job a wee bit easier. The bottom beading on the window frames was made by gluing a pieces of evergreen microstrip across at the right height and then removing the bits between windows. Its not ideal but they do all line up which is a bit more important (I'll have to paint it now to check it doesn't look silly and the blemishes are not too deep).

Finally I tacked the bits above the windows. This was cut in one piece from a piece of 1mm plasticard. I was not sure how I was going to do all the raised beading on the edges, and it was a pleasant surprise to discover that the burrs raised from cutting the plastic sheet were just about right. The beading running down the center of this bit was done again using microstrip.

So, here's how it looks after a night being left to dry (pressed under a piece of glass so that it would not warp)

'Don't look too close'

Saturday, September 26, 2009

These are a few of my Favourite Things...

AmFet writes: I'm always slightly amused by the way that us hobbyists have "favourites", whether it be locomotives, carriages, stations, sleepers etc. For some reason, there is one locomotive out of a class of many that somehow does it for us more than the others......for some reason, I like DC4507, but am strangely non-commital towards 4611.

Anyway, here is one of my favourites: DX5120.

I like her as I spent half of my loco pass in her cab, running W(h)anganui - Whareroa with train 544 2 days running earlier this year. Sure, she was old and scungy and kept having arguments over the dynamics with 5074 behind, but it was a real experience riding in a virtually unmodified Phase 1 DX when most of her brethren had been updated with all the mod cons. That she turned up at all on the milk trains was a real suprise to a lot of people. Foibles? Well, Drew could probably fill in a few, but from the left side of the cab....well, my seat didnt adjust properly and the arm rest was broken, and when ever the dynamics went on (and after 5074 had given up arguing), I got a nice warm gust of air through the open window from the dynamic vent behind the cab. But on a warm summers day, there isnt anything quite like sitting in a DX cab with your feet up and the front door open.....

Anyway, I spent the next few months waiting for the right moment to photograph her in all her TranzRail Blue glory, but then things...happened. And she was sent to Hutt Shops, then got caught up in the DXB rebuild program.

I just so happened to be at Hutt Shops last Friday for work, so took the chance to see how she was getting on....and with the help of a suitably located ladder and platform ("Just checking the network junction box up there..."), got this:

I dearsay she'll be out soon, so again I'll be able to get the warm fuzzies seeing her at the depot from my morning train....what a geek.

Anyway, here is one of my favourites: DX5120.

I like her as I spent half of my loco pass in her cab, running W(h)anganui - Whareroa with train 544 2 days running earlier this year. Sure, she was old and scungy and kept having arguments over the dynamics with 5074 behind, but it was a real experience riding in a virtually unmodified Phase 1 DX when most of her brethren had been updated with all the mod cons. That she turned up at all on the milk trains was a real suprise to a lot of people. Foibles? Well, Drew could probably fill in a few, but from the left side of the cab....well, my seat didnt adjust properly and the arm rest was broken, and when ever the dynamics went on (and after 5074 had given up arguing), I got a nice warm gust of air through the open window from the dynamic vent behind the cab. But on a warm summers day, there isnt anything quite like sitting in a DX cab with your feet up and the front door open.....

Anyway, I spent the next few months waiting for the right moment to photograph her in all her TranzRail Blue glory, but then things...happened. And she was sent to Hutt Shops, then got caught up in the DXB rebuild program.

I just so happened to be at Hutt Shops last Friday for work, so took the chance to see how she was getting on....and with the help of a suitably located ladder and platform ("Just checking the network junction box up there..."), got this:

I dearsay she'll be out soon, so again I'll be able to get the warm fuzzies seeing her at the depot from my morning train....what a geek.

The things you find.

Tonight while looking for something else, I came across this. (you will need quicktime or be running firefox to view it). Click on the photo to follow the link.

What is interesting from my point of view is the film of the shunting at Summit. I was not sure how they had rejoined the trains while removing the loco's. Also quite interesting to note is a complete lack of regard for health and safety regulations.

What is interesting from my point of view is the film of the shunting at Summit. I was not sure how they had rejoined the trains while removing the loco's. Also quite interesting to note is a complete lack of regard for health and safety regulations.

Friday, September 25, 2009

For the rest of you

The comments section suggests that some out there might be growing weary of my fascination with boiling water machines and the products of English electric, as they can't remember them. Personally I struggle to remember parts of last week.

Since Darryl has gone to Romania to chase vampires and steam trains, Its up to me so I'll post this picture of one of Drew's offices this week.

Since Darryl has gone to Romania to chase vampires and steam trains, Its up to me so I'll post this picture of one of Drew's offices this week.

'Morning Miss Jones, 11 minutes late, leaves on the line at Waitotara. Take a memo....'

For those of you out their currently making models of Milk tankers, I hope you will include the height differences as well. I assume they were all empty?

Really old wagons

Another shot from the 'prototypes I can find' files.

At Founders park they also have an old L1 wagon underframe that someone dug out of a swamp or something. This is quite instructional as its always the bits that you can never see.

Unfortunately I didn't have the measuring tape with me so I couldn't see how long the axles should have been.

At Founders park they also have an old L1 wagon underframe that someone dug out of a swamp or something. This is quite instructional as its always the bits that you can never see.

Unfortunately I didn't have the measuring tape with me so I couldn't see how long the axles should have been.

Thursday, September 24, 2009

The only railway I've got

I wandered down to Founders today to take some photos (and buy some more beer, their special brew is drinking very well, pity I got the last of it:v). Previous visits to the railway to get detailed photos of the ballast wagons had been thwarted as they were parked on a siding surrounded by trees. Today they were parked in front of the station. Just as an experiment I paced off 120' and took a picture. Well, it was probably only 110', the extra would have put me in the duck pond.

"Could someone please move that Pukeko?"

I've always liked the look of the Yb as a wagon, and have one I assembled 15 years ago from the bottom part of a resin Yc hopper. However today I could compare them both side by side, and while I didn't take any pictures for comparison, the Yc hopper is about 6" larger all round. The underframe is going to be a bit more difficult to make as well as its all channel and very small. and then there's all the brake gear which is very immodestly displayed for all to see.

Maybe I'll just have to make do with a set of Yc's for a ballast train.

Wednesday, September 23, 2009

Observing

This evening I'm doing another review. this time its a bit different as its the 3rd railway magazine produced in this country, the Railway Observer which is the official voice of the New Zealand Railway and Locomotive Society. I picked this up in the local magazine shop while looking in vain to see if the latest Railfan was out. What caught my eye was the 6 pages of previously unpublished pictures of the Rimutaka incline. I sidled up to the counter, passed over my money and asked for a plain brown bag. The price was $11.20.

Now before we start here i have many happy memories of reading this magazine in the early and mid 80's back when the Observer was a source of information both historical and up to date.

So, what does we get for our shiny coin. In this issue, there is also an 8 page article on Vulcan railcars, which in the main focuses on their engines (Licenced by Vulcan from some Danish outfit), their shipping out to new Zealand (it was the second railcar which was lost when its ship was torpedoed; there's the answer to a railway quiz question right there), and a short (very) history of their service here. There is a plan and also a picture of the motor bogie without the lid on, which is quite instructive. There is a short article on the wellington electrification upgrade (photos of men in High vis gear doing stuff), the Rimutaka pictures, 8 pages on the early construction of the Otago central line, and an update on the restoration of Ab 608. Finally there's a couple of pages of short notes and a few letters to the editor and some bok/DVD reviews. The articles are quite 'dry' and don't seem to convey as much information as similar text in the Railfan, and there are not quite as many good photo's either.

So, final verdict? Its sort of a Railfan lite, but it is only a couple of dollars cheaper. It has not really changed content wise since the 1980's apart from moving from A5 to A4 format. Its not something I would purchase unless it had something I really wanted.

(The views expressed in this review are those of the proprietor of this blog, who has put his tin hat on to await the invertible incoming flames)

Now before we start here i have many happy memories of reading this magazine in the early and mid 80's back when the Observer was a source of information both historical and up to date.

So, what does we get for our shiny coin. In this issue, there is also an 8 page article on Vulcan railcars, which in the main focuses on their engines (Licenced by Vulcan from some Danish outfit), their shipping out to new Zealand (it was the second railcar which was lost when its ship was torpedoed; there's the answer to a railway quiz question right there), and a short (very) history of their service here. There is a plan and also a picture of the motor bogie without the lid on, which is quite instructive. There is a short article on the wellington electrification upgrade (photos of men in High vis gear doing stuff), the Rimutaka pictures, 8 pages on the early construction of the Otago central line, and an update on the restoration of Ab 608. Finally there's a couple of pages of short notes and a few letters to the editor and some bok/DVD reviews. The articles are quite 'dry' and don't seem to convey as much information as similar text in the Railfan, and there are not quite as many good photo's either.

So, final verdict? Its sort of a Railfan lite, but it is only a couple of dollars cheaper. It has not really changed content wise since the 1980's apart from moving from A5 to A4 format. Its not something I would purchase unless it had something I really wanted.

(The views expressed in this review are those of the proprietor of this blog, who has put his tin hat on to await the invertible incoming flames)

Tuesday, September 22, 2009

Another post without a mention of guards vans

Yes, I'm managing to hold back for yet another post. This ones a bit late today but I though I would let discussion from the previous post run its course. Thanks to all those who replied for keeping the debate positive, hopefully the Guild will take some of the comments on board.

Tonight's ramble is on a currently vexing problem, wheels. More accurately axles. The main problem is one of length. Back whenever Peco made its first N scale wagons, some rocket scientist made one of those typically British decisions similar to those that have systematically destroyed every sensible scale/gauge relationship they have been involved in. Namely deciding that 15mm axles were a good idea regardless of the actual scale implications (for all you S scale readers, this scales to a 28mm axle) . To get round the overly long axle lengths the pin point bearing bits were buried way out in the axleboxes.

The unhappy sequel to all is that our merry band of modelers who are now looking to make underframes and bogies of a more scale appearance face having to do something similar with brass pin point bearings, which is a pain in the ass. Thus the search is on to find a replacement source of wheels. So far Markits (no answer) and Parkside Dundas ('how many do you want, we need to make then specially', which is a small production run killer ) have been tried, but if you only want 2 dozen wheelsets to check if your idea will actually work, you're 9maybe should read we're) screwed.

I'm now mulling over the pros and cons of actually joining the 2mm association just to get my hands on some wagon wheels (regauged) that are sort of correct, and the possibly trackwork implications that finescale wheels entail. The alternative is to try to locate someone locally who would turn axles up locally, and just import the wheel disc. North Yard is out, primarily because we are to small a market, but I'd be interested to hear of any others.

Tonight's ramble is on a currently vexing problem, wheels. More accurately axles. The main problem is one of length. Back whenever Peco made its first N scale wagons, some rocket scientist made one of those typically British decisions similar to those that have systematically destroyed every sensible scale/gauge relationship they have been involved in. Namely deciding that 15mm axles were a good idea regardless of the actual scale implications (for all you S scale readers, this scales to a 28mm axle) . To get round the overly long axle lengths the pin point bearing bits were buried way out in the axleboxes.

The unhappy sequel to all is that our merry band of modelers who are now looking to make underframes and bogies of a more scale appearance face having to do something similar with brass pin point bearings, which is a pain in the ass. Thus the search is on to find a replacement source of wheels. So far Markits (no answer) and Parkside Dundas ('how many do you want, we need to make then specially', which is a small production run killer ) have been tried, but if you only want 2 dozen wheelsets to check if your idea will actually work, you're 9maybe should read we're) screwed.

I'm now mulling over the pros and cons of actually joining the 2mm association just to get my hands on some wagon wheels (regauged) that are sort of correct, and the possibly trackwork implications that finescale wheels entail. The alternative is to try to locate someone locally who would turn axles up locally, and just import the wheel disc. North Yard is out, primarily because we are to small a market, but I'd be interested to hear of any others.

Monday, September 21, 2009

3rds a charm

Back to guards vans again.

My previous attempts to add some detail to the bogies with microstrip looked really good, but were both (here is the first, the second was a bit worse and thankfully goes unrecorded).

Today I was thinking about something else when I cracked the obvious way to do this (hint; if you are trying to solve a problem either have a shower or think about something else, its far quicker). Take a piece of brass microstrip and mark out the correct length (the top of the bogie plus about 5mm each end), with about 15mm extra at each end. At the correct points bend the strip 180 degrees on itself and clamp with pliers. Hold about 2mm of this in the pliers and then bend the short section back 90 degrees and make sure that the bend is square. then bend to about 70 degrees from normal and cut down to about 5mm each extra bit. This should then glue onto the top of the bogies. Hopefully the picture explains it a bit better.

This seems to be the easiest method I've come up with for adding this detail, and requires the least in the way of soldering (my favorite value for this; none)

UPDATE; got a picture of the reall thing today, and It apepars that my solution is almost identical looks wise to the real thing.

My previous attempts to add some detail to the bogies with microstrip looked really good, but were both (here is the first, the second was a bit worse and thankfully goes unrecorded).

Today I was thinking about something else when I cracked the obvious way to do this (hint; if you are trying to solve a problem either have a shower or think about something else, its far quicker). Take a piece of brass microstrip and mark out the correct length (the top of the bogie plus about 5mm each end), with about 15mm extra at each end. At the correct points bend the strip 180 degrees on itself and clamp with pliers. Hold about 2mm of this in the pliers and then bend the short section back 90 degrees and make sure that the bend is square. then bend to about 70 degrees from normal and cut down to about 5mm each extra bit. This should then glue onto the top of the bogies. Hopefully the picture explains it a bit better.

This seems to be the easiest method I've come up with for adding this detail, and requires the least in the way of soldering (my favorite value for this; none)

UPDATE; got a picture of the reall thing today, and It apepars that my solution is almost identical looks wise to the real thing.

Sunday, September 20, 2009

Containing the Trackgang UK

DB says (beginning in late July): I figured I should order some Trackgang NZ120 kits since they went to all that effort. The website was easy to use and much to my delight, a pair of UKs arrived within two days, in plenty of time for the trip home.

DB says (beginning in late July): I figured I should order some Trackgang NZ120 kits since they went to all that effort. The website was easy to use and much to my delight, a pair of UKs arrived within two days, in plenty of time for the trip home.The day after getting home, I started assembling one from the surprisingly large number of parts and the wagon itself went together nicely.

Some quick notes on the wagon's nether regions - the castings are excellent, and the underframe is quite clever, but the instructions are a little misleading with respect to the neat transverse angle braces, suggesting (to my eyes) that a number of them should have the angles removed on one side only. After consulting a few pictures of real UKs: four of the braces should be placed 'as-is' against the raised guides cast into the underside (about where the twistlocks that support the centre 10-foot container spot go - although these guides are a little wider than they should be), another one should be placed 'as-is' in the centre spot, and another one at each end. The remaining braces go onto the remaining marked locations with both their side angles cut away. The bracing is thus identical on both sides of the wagon. Well, I'm glad that's cleared that up. There is a great UK underside shot and an NZ120 plan in the Dec 2000 Model Railway Journal and I've provided the cleverly marked top picture to make it all crystal clear. Not. The VCC Models website also has an excellent diagram of the UK undersides at the bottom of their S scale kit instructions (warning: 800k pdf file).

It would be nice if the twistlocks were cast into the one-piece top as they are quite the pain in the rear to cut off a sprue, modify the side wings and stick on 24 times per wagon. Unless of course you enjoy chasing tiny bits of metal around the workbench. I attached most of them except for one of the end sets because they pee'd me off so much. They do look the part though.

It would be nice if the twistlocks were cast into the one-piece top as they are quite the pain in the rear to cut off a sprue, modify the side wings and stick on 24 times per wagon. Unless of course you enjoy chasing tiny bits of metal around the workbench. I attached most of them except for one of the end sets because they pee'd me off so much. They do look the part though.Unfortunately I ended up in that same place that I always seem to, after working on the rolly bits for well over an hour. I don't seem to have enough hands (having only two) to be able to assemble Trackside/Trackgang underframes and bogies without running most of the way through the Swearing Thesaurus. In a fit of frustration I pulled out a 9mm DG and hit myself with it for a week...

If you can assemble the bogies squarely, they can be encouraged to roll down the Rimutaka Incline, but that's not ideal if you want to have 20 or 30 wagons on a train on a grade on a curve on a layout. And as most of my old Trackside stash came pre-assembled, this isn’t merely, as you would normally have surmised, me screwing up.

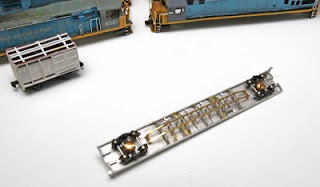

So again, out came some brass bearings from the English 2mm Society and I tried both cup and high hat varieties in various experiments, completing three bogies. The bogies all run very well when fitted with bearings (spinning along in MT style), and the bogie frames are stiff enough to prevent the wheels falling out. This is the good. The bad is that while they look good from side-on, they don't from above because with the depth of castings, even with indented bearings (bogie castings drilled out) or even with no bearings, the assembled bogies are almost as wide as the wagon deck. So after putting the 9mm DG away, I stuck on some Kato bogies and began to breathe again...

Par-for-the-course ranting on bogies and couplers aside, I like the Trackgang UK - especially the look of the open underframe. It looks a zillion percent better than my solid cast ones (left vs right respectively in the pic above).

Par-for-the-course ranting on bogies and couplers aside, I like the Trackgang UK - especially the look of the open underframe. It looks a zillion percent better than my solid cast ones (left vs right respectively in the pic above).Perhaps more importantly, at the end of this extended project (I wrote a harsher draft of this post almost two months ago), I'm at peace: Trackgang has the only range of NZ120 rolling stock kits on the market at the moment and their wagons are incredible value for money. As long as you remember that and set your expectations accordingly, you'll be a happy camper. Sure this UK could be easier to assemble and have better running gear, but then it wouldn't cost 23 dollars now would it. As my namesake on The Castle would say, "You couldn't buy the materials for that."

Saturday, September 19, 2009

To join or not to join.

I have sitting somewhere in my room at the moment an application form for NZMRG membership. Normally I would have fired it off ages ago, but I'm in 2 minds.

On one hand its $45 for 4 issues, which is cheaper than at the local magazine shop, however if I buy there I am supporting a local business.

I'm finding the articles are all either on other scales or feature prototypes that I'm not particularly interested in ( they have even stopped drawing the plans in NZ120). The age old argument of course is 'why don't you write them yourself?' In this case that's not particularly valid (after all, you are reading this aren't you, and I did write it). Its not overly easy to actually write an article for the journal any more. the pictures that they require are 3000 pixels square (or something similar, it comes out to 2MB per picture). Now for a man who is a point and click photographer and wouldn't know where to start looking for these settings ( and I'm not sure if my 7 year old camera is even good enough for that) that's a bit of an ask as well. Compare that to the demented ramblings here, where I bang of the pictures, reduce the file size (to make it easier for those on a dial up connection), and upload them with a bit of drivel in between to connect them. All from the comfort of my wee computer room hole (sort of like a hobbit hole but with more alcohol and less wizards).

I'll admit that old journals are a great source of plans (the guards van saga is an off-shoot of this) but that's going back over 30-40 odd years (I'd love to see the whole older collection PDF'ed so that you could buy them).

Its just a pity there could not be some faster more up to date method of passing information.

(This post brought to you by a mixture of boredom at work, as there is only so much office golf you can play, and several beers at home. Cheer's).

PS, I'll probably join, but only if they throw in a quarterly column :v)

Friday, September 18, 2009

From the Archives: The Dead Sea Scrolls of NZ Model Railways

AmFet writes: While puddling through the ONTRACK archives at work on Wednesday looking for bridge diagrams (for Bridge 41 just out of Patea, if you must know) I came across something that really did make my ticker skip a beat: The plans for the New Zealand Government Railways display at the 1940 Centennial Exhibition and in particular the 1 Gauge railway that was included.

For those bought up with Joyce Roberts book on her father Frank, this layout will need no introduction: Frank Roberts is widely known as one of the first true model railway craftsman in this country, and many of his glorious models can still be seen at Te Papa in Wellington. For the show he built 2 new locomotives, K916 and Ab608 to go with the large stable of locomotives that he already owned. If you havent read the book, I implore you to do so.

However, up until now very little written information about the layout they ran on has been found. The journal had an article a while back which seemed to have rough pencil sketch of the layout with a few tidbits and personal memories. Hopefully, this wee blog post in an unassuming corner of the internet will change all that.

Drawing 1: Overall view. The stairs at either end led up to a mezzanine display floor. A viaduct was included at the left hand end and a through station with yard and engine shed filled the foreground. At the back, the main line divides into two (possibly the rear track was in a workshop?). The rectangle behind the station was the operators pit that included a fully interlocked signal and lever frame.

Drawing 2: Left hand end, showing the start of the double track (with left hand running) and the back track making a reappearance.

Drawing 3: Right hand end showing the extensive yard and the slightly out of place engine shed (with turntable). The back track seems to have a grade seperated crossing on it, but this doesnt show on the other plans? Curious....

Drawing 4: Being Railway Engineers, the lanscape was fastidiously documented. Here are all the cross sections and levels for the entire viewable section as well as a pencil sketch of the backdrop. The viaduct is shown here, and a small bridge over the "gorge" has appeared to the left of the first set of points.

Drawing 5: A construction drawing that will reward close study. Note the drawings for the "Control Pit" that includes the "Interlocking Machine" and that the viaduct and gorge now have topographical relief lines.

Drawing 6: A quick look at the mezzanine displays which included (among other things) a selection of trolleys mounted on some 85lb rail, a class "K" cab and front end (surely not real?), a sleeping cabin and a tablet machine. Phew!

Drawing 7: This is the viaduct at the left hand end which (using rough guess-timation) must have been about 600 high.

Drawing 8: A No 1 gauge turnout, anyone?? Just to put all this in perspective, the curve of this is 16' radius...thats big in anyones language! It seems the minimum radius on the whole layout was the 14' horseshoe at the left hand end, while the right hand curves were all a more sedate 16'.

Well, thats it....a fascinating look at what must have been a spectacular layout to view in action. If you lost the stupid out-of-proportion engine shed, it would make an ideal exhibition layout in any scale...any takers?

MD writes; Here is the link to the railway collection at Te Papa which includes Frank Roberts collection. Its amazing to think that these models were assembled with a minimum of tools, and possibly without plans (sounds like my workbench some evenings, though I don't know if Frank drank)

For those bought up with Joyce Roberts book on her father Frank, this layout will need no introduction: Frank Roberts is widely known as one of the first true model railway craftsman in this country, and many of his glorious models can still be seen at Te Papa in Wellington. For the show he built 2 new locomotives, K916 and Ab608 to go with the large stable of locomotives that he already owned. If you havent read the book, I implore you to do so.

However, up until now very little written information about the layout they ran on has been found. The journal had an article a while back which seemed to have rough pencil sketch of the layout with a few tidbits and personal memories. Hopefully, this wee blog post in an unassuming corner of the internet will change all that.

Drawing 1: Overall view. The stairs at either end led up to a mezzanine display floor. A viaduct was included at the left hand end and a through station with yard and engine shed filled the foreground. At the back, the main line divides into two (possibly the rear track was in a workshop?). The rectangle behind the station was the operators pit that included a fully interlocked signal and lever frame.

Drawing 2: Left hand end, showing the start of the double track (with left hand running) and the back track making a reappearance.

Drawing 3: Right hand end showing the extensive yard and the slightly out of place engine shed (with turntable). The back track seems to have a grade seperated crossing on it, but this doesnt show on the other plans? Curious....

Drawing 4: Being Railway Engineers, the lanscape was fastidiously documented. Here are all the cross sections and levels for the entire viewable section as well as a pencil sketch of the backdrop. The viaduct is shown here, and a small bridge over the "gorge" has appeared to the left of the first set of points.

Drawing 5: A construction drawing that will reward close study. Note the drawings for the "Control Pit" that includes the "Interlocking Machine" and that the viaduct and gorge now have topographical relief lines.

Drawing 6: A quick look at the mezzanine displays which included (among other things) a selection of trolleys mounted on some 85lb rail, a class "K" cab and front end (surely not real?), a sleeping cabin and a tablet machine. Phew!

Drawing 7: This is the viaduct at the left hand end which (using rough guess-timation) must have been about 600 high.

Drawing 8: A No 1 gauge turnout, anyone?? Just to put all this in perspective, the curve of this is 16' radius...thats big in anyones language! It seems the minimum radius on the whole layout was the 14' horseshoe at the left hand end, while the right hand curves were all a more sedate 16'.

Well, thats it....a fascinating look at what must have been a spectacular layout to view in action. If you lost the stupid out-of-proportion engine shed, it would make an ideal exhibition layout in any scale...any takers?

MD writes; Here is the link to the railway collection at Te Papa which includes Frank Roberts collection. Its amazing to think that these models were assembled with a minimum of tools, and possibly without plans (sounds like my workbench some evenings, though I don't know if Frank drank)

Advanced warning

No post at the regular time today. However, check back at 6:30 tonight for some more model railway archeology.

Thursday, September 17, 2009

Couplers mk 2

I've been doing a wee bit more work on my non working NZR couplers and have come up with a mk 2 prototype for 4 wheeled wagons.

This is designed to fit into the Trackgang coupler pocket. again, no high tech moving parts, but I have included the brake hose on the side. Not sure if I can add sidechains as well. The head of the coupler is still on the big side, but it still looks OK from 2'

I have to do a bit of thinking about adapting this for bogie wagons, maybe by using the base of the Trackgang knuckle coupler and attaching the head to the end in place of the knuckle.

Also, does anyone have a good local source of the Microtrains coupler range or do I have to go overseas?

This is designed to fit into the Trackgang coupler pocket. again, no high tech moving parts, but I have included the brake hose on the side. Not sure if I can add sidechains as well. The head of the coupler is still on the big side, but it still looks OK from 2'

I have to do a bit of thinking about adapting this for bogie wagons, maybe by using the base of the Trackgang knuckle coupler and attaching the head to the end in place of the knuckle.

Also, does anyone have a good local source of the Microtrains coupler range or do I have to go overseas?

Wednesday, September 16, 2009

The're back....

Just to let you all know that I have been plodding along with the 30' vans, so there is indeed no escape.

This week has just seen the assembly of the sides and ends, and the various extra bits added. Roof's are next, but I might have to buy some balsa wood of the correct thickness (the stuff I already have is 6mm thick, but not really thick, its just 'special')

Also, I've finally got to 'finishing' my 47' van. its been dirtied up a bit, possibly too much given that its probably going to wind up on a relief express or a local Wellington train.

This week has just seen the assembly of the sides and ends, and the various extra bits added. Roof's are next, but I might have to buy some balsa wood of the correct thickness (the stuff I already have is 6mm thick, but not really thick, its just 'special')

Also, I've finally got to 'finishing' my 47' van. its been dirtied up a bit, possibly too much given that its probably going to wind up on a relief express or a local Wellington train.

Tuesday, September 15, 2009

'And just where is this going'

Methinks the lady of the house is suspicious....

I've promised that I'm not going to use the bedroom, the living room or the kitchen, but i may have been a bit rash. cutting the bits for the 2 curved modules was fun 9not0 and they don't quite fit right.

now I suppose i have to build something on them.

I've promised that I'm not going to use the bedroom, the living room or the kitchen, but i may have been a bit rash. cutting the bits for the 2 curved modules was fun 9not0 and they don't quite fit right.

now I suppose i have to build something on them.

Monday, September 14, 2009

Moana 6: Appetite for De Structure - The Station

DB says: I'd been putting the station off because I knew it would be hard. Right. Grimace and bear it.

I guessed the station size from pictures and the available space, and as such it's probably 2-3cm longer and a few mm higher than it should be, but I needed to do some backdrop hiding.

The main (long) side was cut out of a thickish piece of plasticard and a thinner body-double that would be laminated on top. The thin piece was scribed with 'boards' using a crusty knife and ruler (Rhys's 2mm scribed Evergreen styrene would have been helpful, but he refused to courier me some). When you scribe styrene, it starts to curl, so I roughly scribed the back of the thin sheet with boards as well, which balances out the stresses and causes the sheet to stop warping. I really should be an engineer with my impressive grasp of plastic particle physics. The approximate locations of windows and doors were penciled onto the 'outside sheet of boards' and cut out with my blunt knife. If you're following along at home, treat yourself to a fresh blade. Given that I'm not putting an interior in this, I used a black permanent marker to black out the window openings on the backing piece as it's much easier to do this now than to paint between all the window details once they are in place later on.

The approximate locations of windows and doors were penciled onto the 'outside sheet of boards' and cut out with my blunt knife. If you're following along at home, treat yourself to a fresh blade. Given that I'm not putting an interior in this, I used a black permanent marker to black out the window openings on the backing piece as it's much easier to do this now than to paint between all the window details once they are in place later on.  The two halves were then stuck together and plasticard strip used to frame out windows and door frames. The doorway at the left was filled with some sort of thin pre-scribed wood sheety stuff, and the other two panel doors are thin plastic rectangles with panel holes cut out to reveal the thick plasticard backing sheet, giving a 3D look.

The two halves were then stuck together and plasticard strip used to frame out windows and door frames. The doorway at the left was filled with some sort of thin pre-scribed wood sheety stuff, and the other two panel doors are thin plastic rectangles with panel holes cut out to reveal the thick plasticard backing sheet, giving a 3D look. End shapes were guestimated, scribed, and cut out of some thick styrene (corrugated as luck would have it - just some stuff that was begging to be used up) and then Moana could finally stand on her feet. Lazy fool that I am, I had no intention of making a backside to the station, but added a middle profile to keep the roof and verandah from sagging.

End shapes were guestimated, scribed, and cut out of some thick styrene (corrugated as luck would have it - just some stuff that was begging to be used up) and then Moana could finally stand on her feet. Lazy fool that I am, I had no intention of making a backside to the station, but added a middle profile to keep the roof and verandah from sagging. Balsa was used for the sub-roof (isn't it funny that balsa, that most primitive and childlike of modelling substances, still plays such a vital part in my modeling?) and this was covered with the last of the overscale HO corrugated aluminium sheet left over from the goods shed. I needed to use two pieces here, one for each end, but the join is well hidden now that the paint is on. I used acrylic Flat Gull Gray (my favourite paint these days) for the walls, and some old Burlington Northern green darkened with a few blobs of black for the trim and roof. And that's that really. A wash of black acrylic was added to the roof to bring out the texture, and the 'Moana' lettering on the verandah was drawn in using a fine tipped permanent marker. I didn't say it was going to be pretty...

Balsa was used for the sub-roof (isn't it funny that balsa, that most primitive and childlike of modelling substances, still plays such a vital part in my modeling?) and this was covered with the last of the overscale HO corrugated aluminium sheet left over from the goods shed. I needed to use two pieces here, one for each end, but the join is well hidden now that the paint is on. I used acrylic Flat Gull Gray (my favourite paint these days) for the walls, and some old Burlington Northern green darkened with a few blobs of black for the trim and roof. And that's that really. A wash of black acrylic was added to the roof to bring out the texture, and the 'Moana' lettering on the verandah was drawn in using a fine tipped permanent marker. I didn't say it was going to be pretty...

I suppose in hindsight I didn't need to put in as much heartburn over building and painting all that window framing as the side is barely visible, but on the other hand, at least now you won't be able to see what a bollocks I made of some of them either. There's always a silver lining...

The station is a little bit long, but that's OK. What's not is that while painting the thing, I made the mistake of Googling up some images of Moana (I was surprised how many are out there) and they revealed that the station has undergone some changes since the pictures in the Peter Hodge article were taken. The wooden door at the left side seems to have been covered up now as if it were never there, and some windows have appeared in that little protrusion at the left of the building. Ah well. The observant will also note that the goods shed isn't opposite the station where it's supposed to be - I wanted it closer to the footbridge to hide the 'tunnel' into the staging yard.

So at two days elapsed time and maybe, at a stretch, four hours of actual effort, that didn't take as long to give birth to as feared -I certainly spent a long time fretting about it. Quite a long ge-station you might say. You've been a great audience, and I'll be here all week.

I guessed the station size from pictures and the available space, and as such it's probably 2-3cm longer and a few mm higher than it should be, but I needed to do some backdrop hiding.

The main (long) side was cut out of a thickish piece of plasticard and a thinner body-double that would be laminated on top. The thin piece was scribed with 'boards' using a crusty knife and ruler (Rhys's 2mm scribed Evergreen styrene would have been helpful, but he refused to courier me some). When you scribe styrene, it starts to curl, so I roughly scribed the back of the thin sheet with boards as well, which balances out the stresses and causes the sheet to stop warping. I really should be an engineer with my impressive grasp of plastic particle physics.

The approximate locations of windows and doors were penciled onto the 'outside sheet of boards' and cut out with my blunt knife. If you're following along at home, treat yourself to a fresh blade. Given that I'm not putting an interior in this, I used a black permanent marker to black out the window openings on the backing piece as it's much easier to do this now than to paint between all the window details once they are in place later on.

The approximate locations of windows and doors were penciled onto the 'outside sheet of boards' and cut out with my blunt knife. If you're following along at home, treat yourself to a fresh blade. Given that I'm not putting an interior in this, I used a black permanent marker to black out the window openings on the backing piece as it's much easier to do this now than to paint between all the window details once they are in place later on.  The two halves were then stuck together and plasticard strip used to frame out windows and door frames. The doorway at the left was filled with some sort of thin pre-scribed wood sheety stuff, and the other two panel doors are thin plastic rectangles with panel holes cut out to reveal the thick plasticard backing sheet, giving a 3D look.

The two halves were then stuck together and plasticard strip used to frame out windows and door frames. The doorway at the left was filled with some sort of thin pre-scribed wood sheety stuff, and the other two panel doors are thin plastic rectangles with panel holes cut out to reveal the thick plasticard backing sheet, giving a 3D look. End shapes were guestimated, scribed, and cut out of some thick styrene (corrugated as luck would have it - just some stuff that was begging to be used up) and then Moana could finally stand on her feet. Lazy fool that I am, I had no intention of making a backside to the station, but added a middle profile to keep the roof and verandah from sagging.

End shapes were guestimated, scribed, and cut out of some thick styrene (corrugated as luck would have it - just some stuff that was begging to be used up) and then Moana could finally stand on her feet. Lazy fool that I am, I had no intention of making a backside to the station, but added a middle profile to keep the roof and verandah from sagging. Balsa was used for the sub-roof (isn't it funny that balsa, that most primitive and childlike of modelling substances, still plays such a vital part in my modeling?) and this was covered with the last of the overscale HO corrugated aluminium sheet left over from the goods shed. I needed to use two pieces here, one for each end, but the join is well hidden now that the paint is on. I used acrylic Flat Gull Gray (my favourite paint these days) for the walls, and some old Burlington Northern green darkened with a few blobs of black for the trim and roof. And that's that really. A wash of black acrylic was added to the roof to bring out the texture, and the 'Moana' lettering on the verandah was drawn in using a fine tipped permanent marker. I didn't say it was going to be pretty...

Balsa was used for the sub-roof (isn't it funny that balsa, that most primitive and childlike of modelling substances, still plays such a vital part in my modeling?) and this was covered with the last of the overscale HO corrugated aluminium sheet left over from the goods shed. I needed to use two pieces here, one for each end, but the join is well hidden now that the paint is on. I used acrylic Flat Gull Gray (my favourite paint these days) for the walls, and some old Burlington Northern green darkened with a few blobs of black for the trim and roof. And that's that really. A wash of black acrylic was added to the roof to bring out the texture, and the 'Moana' lettering on the verandah was drawn in using a fine tipped permanent marker. I didn't say it was going to be pretty...

I suppose in hindsight I didn't need to put in as much heartburn over building and painting all that window framing as the side is barely visible, but on the other hand, at least now you won't be able to see what a bollocks I made of some of them either. There's always a silver lining...

The station is a little bit long, but that's OK. What's not is that while painting the thing, I made the mistake of Googling up some images of Moana (I was surprised how many are out there) and they revealed that the station has undergone some changes since the pictures in the Peter Hodge article were taken. The wooden door at the left side seems to have been covered up now as if it were never there, and some windows have appeared in that little protrusion at the left of the building. Ah well. The observant will also note that the goods shed isn't opposite the station where it's supposed to be - I wanted it closer to the footbridge to hide the 'tunnel' into the staging yard.

So at two days elapsed time and maybe, at a stretch, four hours of actual effort, that didn't take as long to give birth to as feared -I certainly spent a long time fretting about it. Quite a long ge-station you might say. You've been a great audience, and I'll be here all week.

Sunday, September 13, 2009

XP van review; the finale

When we left the review last time, I had finished with the assembly of the body and roof. Attention was then turned to the chassis. I started by drilling the axle bearings out slightly as I've discussed previously. Taking one solebar equal amounts of material were removed from each end until it fitted between the headstocks. This was then glued into position. The second solebar had the same treatment, but much more carefully. The wheels were test fitted and the ends of the solebar filed away until the solebar both fitted between the headstocks and, more importantly, the axles were parallel. When everything was satisfactory the solbar was glued into place. lastly the brake bits were attached.

At this point I noticed I had forgotten to glue the roof ventilators into place. These were carefully (as there's no spares) cut off the sprues and glued into position. I used a ruler edge to check thats the 4 ventilators on either side lined up correctly (it 'stands out like dogs balls' when things like this don't line up).

To finish the chassis was painted black and the body and roof were painted white. A bit of shading (I still have to give in a light dusting of brake dust) and there we have it.

As a personal; comment here, I'm liking the trackgang range. I've not run across any kits that are bad yet (well, I've only assembled 3 plus some underframes). Its a lot easier than scratch building everything, in fact its almost like a holiday.

At this point I noticed I had forgotten to glue the roof ventilators into place. These were carefully (as there's no spares) cut off the sprues and glued into position. I used a ruler edge to check thats the 4 ventilators on either side lined up correctly (it 'stands out like dogs balls' when things like this don't line up).

To finish the chassis was painted black and the body and roof were painted white. A bit of shading (I still have to give in a light dusting of brake dust) and there we have it.

As a personal; comment here, I'm liking the trackgang range. I've not run across any kits that are bad yet (well, I've only assembled 3 plus some underframes). Its a lot easier than scratch building everything, in fact its almost like a holiday.

Saturday, September 12, 2009

Moana 5: Structurally Unsound

DB says: With the recent greenification of Moana, now would be a good time to make my first structures of this millenium. Yes, I'm a little rusty, and it shows, but we both know that if you were hoping to see works of art, you'd be on Leonardo DaVinci's blog and not this one.

DB says: With the recent greenification of Moana, now would be a good time to make my first structures of this millenium. Yes, I'm a little rusty, and it shows, but we both know that if you were hoping to see works of art, you'd be on Leonardo DaVinci's blog and not this one. The goods shed was formed in record time around a base of foamboard. Using a few pictures and some model wagons to guess the proportions, I cut out a floor and added walls and ends on top of this with PVA (contact glue will melt the foam in the foamboard edges). A roof of balsawood was stuck on top. In hindsight, now that it's finished, the roof pitch should be a tiny bit steeper, but there you have it.

The goods shed was formed in record time around a base of foamboard. Using a few pictures and some model wagons to guess the proportions, I cut out a floor and added walls and ends on top of this with PVA (contact glue will melt the foam in the foamboard edges). A roof of balsawood was stuck on top. In hindsight, now that it's finished, the roof pitch should be a tiny bit steeper, but there you have it.Once the glue holding this core together had tacked a bit, some fairly fine HO scale corrugated aluminium sheet, which was found lurking in my bag of plasticard bits, was liberally applied to the the card sides of the foamboard on the visible north side, east end and the balsa roof using contact glue - one piece for each (Captain Obvious says: the one piece roof has a bend in it). As these were all big meaty shapes, I scribed in a couple of lengthwise 'join lines' on each with a knife and ruler to represent the layers of corrugated iron sheets, and not terribly well, I might add, as can be seen in the picture above.

The doors and a few bits of styrene strip were splashed on to make it look like some effort and more than ten minutes were expended constructing the shed and before everything had set, paint was already going on.

I used light gray with a few blobs of yellow in it to get the base cream colour first, and freight car brown for the door and some rust blobs. Once this had set, a wash of acrylic black brought out the corrugations, and later that evening, some light gray was drybrushed on the top of the walls to lighten things up a bit (the vertical picture in the previous Moana post shows it in the background in its darker state).

The west end (facing the staging yard) and the south side facing the station won't be visible unless you're trying really hard, and even then, only at an extreme angle, so they only received a rudimentary painting over the foamboard core (no cladding) as can be seen below. Why not do them properly you ask?

The seedy underbelly

My philosophy is that I'd rather steam through something and finish it to a reasonable standard and then get on to the next thing; than spend weeks agonising over perfecting it in the hope of an A+ mark but thus risking getting bogged down and never finishing anything. Either that or I'm lazy in a hyperactive kind of way.

Just in case you hadn't noticed, there's far too much to do in life and far too little time to do it in...

You may recall from that last episode that I recommended the Journal's fine pictures of Moana. To record the correct Journal issue for that post I foolishly removed the magazine from the train room and then the next day had forgotten where I'd left it, so made this hash of an overbridge without pictures. Note to self: D'oh. The handrail posts are a bit widely spaced and a few details are a bit out, but luckily this won't be a terribly visible structure on the layout.

You may recall from that last episode that I recommended the Journal's fine pictures of Moana. To record the correct Journal issue for that post I foolishly removed the magazine from the train room and then the next day had forgotten where I'd left it, so made this hash of an overbridge without pictures. Note to self: D'oh. The handrail posts are a bit widely spaced and a few details are a bit out, but luckily this won't be a terribly visible structure on the layout.The hill it is resting on is a piece of foam painted dark colours (it will be hiding in the shadows behind the goods shed) and sprinkled with some superfine ground foam. The decks of the bridge are balsa, the pain in the patootie handrails are styrene strips, and the last of my 1:120 Preiser 1950s Slovakian Shipbuilders were added to add a little humanity. Oh the humanity.

In the next postcard from Moana: a station.

Friday, September 11, 2009

Loco ideas

Someone on the retrospective NZR group the other day came up with some pictures of Df's in the bay of plenty in the 1970's, and it got me thinking about building one. the question that I did ask was, would it be possible to build one from 2 Dg noses plus new body sides and roof, given that the Dg was supposed to be 1/2 a Df when they were built. The nose is the hardest part to do (a hex on designers who thought that curved loco's were a good idea) so this might be a simple solution.

Or are the 2 loco's completely different and I'm stuffed?

(thanks to John Dennis for the use of the picture, more here)

Thursday, September 10, 2009

Trackgang XP review

A change is as good as a rest they say.

Today we have another review of a Trackgang kit. This time its the XP. I initially brought this to investigate the possibility of converting it to an Xa. 30 seconds after I opened the packet that plan went the way of the dodo. The only thing left? Build it as god intended (well, almost).

The box (Tauranga to Nelson in 24 hrs) contained the following bits. The casting are, as one would expect, crisp with very little flash.

First up I read the instructions (yes, really). As I had already put together several chassis I decided to have a go at the top first. This was in retrospect a very good choice.

The sides and ends go together with minimal filing. I used superglue for initial construction with Araldite to strengthen the joint.

At this point I offered up the floor to the body, and discovered that I was going to need to do a bit of filing to get it to fit. The instructions here are a bit misleading. there are 2 separate sections with the chassis assembly and the body assembly, but the body assembly suggests that you fit the floor in. No mention is made of the solbars etc. If the size of the chassis has to be altered its easier to do it as you assemble it piece by piece.

At this point I offered up the floor to the body, and discovered that I was going to need to do a bit of filing to get it to fit. The instructions here are a bit misleading. there are 2 separate sections with the chassis assembly and the body assembly, but the body assembly suggests that you fit the floor in. No mention is made of the solbars etc. If the size of the chassis has to be altered its easier to do it as you assemble it piece by piece.

Anyway, back to the chase. The assembly order was tossed out the window, and i started by adding the floor, as I thought that the structure would be stronger by adding this first before the roof. I started filing down the floor so that it would fit into the body (there are some nice locating strips to get this correct). I found that i had to remove ~1mm off each end, and also file some material away so that the floor would slot in. The picture sort of shows this, next to an unmodified floor piece at the bottom.

After a fair bit of filing the floor fitted nicely, and it was then Araldited into place.

After a fair bit of filing the floor fitted nicely, and it was then Araldited into place.

Next I added the roof. This required some gentle filing removing material from each side untill it was a tight fit. I araldited this on as well, then filed down the sides as indicated in the instructions (see, I used them for something) untill the join was smooth.

Here we have a kit sitting next to Darryls Xc top. The Xc is slightly larger, but also has other differences in the door, paneling and the lovres being flush vs recessed on the XP.

Theres only the solbars and wheels to go on at the moment, but my general feeling is that this is another good kit (instructions aside) the detail is crisp and it goes together well enough without too much work. Another kit that I would buy more of ( well, I've now got 4 Xc/Xp so probably not, but you all know what i mean).

Today we have another review of a Trackgang kit. This time its the XP. I initially brought this to investigate the possibility of converting it to an Xa. 30 seconds after I opened the packet that plan went the way of the dodo. The only thing left? Build it as god intended (well, almost).

The box (Tauranga to Nelson in 24 hrs) contained the following bits. The casting are, as one would expect, crisp with very little flash.

First up I read the instructions (yes, really). As I had already put together several chassis I decided to have a go at the top first. This was in retrospect a very good choice.

The sides and ends go together with minimal filing. I used superglue for initial construction with Araldite to strengthen the joint.

At this point I offered up the floor to the body, and discovered that I was going to need to do a bit of filing to get it to fit. The instructions here are a bit misleading. there are 2 separate sections with the chassis assembly and the body assembly, but the body assembly suggests that you fit the floor in. No mention is made of the solbars etc. If the size of the chassis has to be altered its easier to do it as you assemble it piece by piece.

At this point I offered up the floor to the body, and discovered that I was going to need to do a bit of filing to get it to fit. The instructions here are a bit misleading. there are 2 separate sections with the chassis assembly and the body assembly, but the body assembly suggests that you fit the floor in. No mention is made of the solbars etc. If the size of the chassis has to be altered its easier to do it as you assemble it piece by piece.Anyway, back to the chase. The assembly order was tossed out the window, and i started by adding the floor, as I thought that the structure would be stronger by adding this first before the roof. I started filing down the floor so that it would fit into the body (there are some nice locating strips to get this correct). I found that i had to remove ~1mm off each end, and also file some material away so that the floor would slot in. The picture sort of shows this, next to an unmodified floor piece at the bottom.

After a fair bit of filing the floor fitted nicely, and it was then Araldited into place.

After a fair bit of filing the floor fitted nicely, and it was then Araldited into place.

Next I added the roof. This required some gentle filing removing material from each side untill it was a tight fit. I araldited this on as well, then filed down the sides as indicated in the instructions (see, I used them for something) untill the join was smooth.

Here we have a kit sitting next to Darryls Xc top. The Xc is slightly larger, but also has other differences in the door, paneling and the lovres being flush vs recessed on the XP.

Theres only the solbars and wheels to go on at the moment, but my general feeling is that this is another good kit (instructions aside) the detail is crisp and it goes together well enough without too much work. Another kit that I would buy more of ( well, I've now got 4 Xc/Xp so probably not, but you all know what i mean).

Wednesday, September 09, 2009

Moana 4: Nothing to see here. Carry on.

DB says: I've been putting in half an hour here and there on Moana this week, although progress has been less dramatic. Scenery danced its way to the far end of the boards and work has progressed on adding some structures. In the shot above you can see a goods shed (I may have to lighten it up a bit) and the balsa decks of a footbridge are barely visible under construction at the extreme end of the visible universe, being held in place by a colourful string of paint pots on the station platform.

DB says: I've been putting in half an hour here and there on Moana this week, although progress has been less dramatic. Scenery danced its way to the far end of the boards and work has progressed on adding some structures. In the shot above you can see a goods shed (I may have to lighten it up a bit) and the balsa decks of a footbridge are barely visible under construction at the extreme end of the visible universe, being held in place by a colourful string of paint pots on the station platform.The shots from the previous Moana blog post didn't really show the scenery well, but perhaps the distant trees in the following shot convey the effectiveness of the 'layered mixing it up' approach as discussed previously. The foreground needs some flaxes and DBR 1213/1267 is obviously having an identity crisis:

Most of the blue background is an old Tehachapi backscene held up while the shot was clicking. This makes me wonder if I should have built a backdrop at this end as well, but the sky on the backscene to the right will continue down into the corner module and hopefully provide the same effect.

Most of the blue background is an old Tehachapi backscene held up while the shot was clicking. This makes me wonder if I should have built a backdrop at this end as well, but the sky on the backscene to the right will continue down into the corner module and hopefully provide the same effect.In this last shot below, work has started on the property in the middle of the pic adjacent to the points at the southwest end. Perhaps this was the station master's house in the good old days? A low weatherboard house will go in here and the fence is up already. Rather than make the dude's back shed, I employed one of Rhys's wee resin huts. I also produced my Modeller's License at this stage and added a trackside shelter and control box ex Rod Murgatroyd that have been sitting in my box of bits for quite some time. This week, an old flock of HO sheep were found wandering through one of my boxes of scenery, so after tailing them, they were put to work in the foreground mowing the grass in forced perspective.

The foamboard station platform is just visible at back right, and one of the 'fancy houses' that Moana has become infested with in the last few years will be represented on the hill out of shot to the right: with a lovely view of the goods shed. I think this will be the first layout/module I've built where the rails and ballast will be the last thing to be added - track here is dummied up for the pictures and to test clearances.

The foamboard station platform is just visible at back right, and one of the 'fancy houses' that Moana has become infested with in the last few years will be represented on the hill out of shot to the right: with a lovely view of the goods shed. I think this will be the first layout/module I've built where the rails and ballast will be the last thing to be added - track here is dummied up for the pictures and to test clearances.Incidentally, although I have taken quite a few pictures of Moana, for the structures I've been referring extensively to the 'Station File: Moana' article in the Feb 1996 Journal, penned by the late Peter Hodge who was one of the great gentlemen of the hobby in NZ. I have about half the Journals going back to the late 1980s and they really are a mine of useful pictures, plans and information. One of these days I'm going to have to rejoin the NZ Model Railway Druids Guild.

Subscribe to:

Posts (Atom)