I know there are a few people out there who are very keen to see the ZH and ZG arrive somewhere close to them so they can run gazillions of them on their layouts. So to that end, here is a report on the latest design iteration (Ver 3.0??)

As I have already stated elsewhere, the main design change was the use of 0.25 styrene for the doors in place of the earlier 1.0 and 0.5mm stuff, both of which proved too thick to be easily handled. This entailed a lot of redrawing of the original plan as the internal formers needed their overall shape changed to accommodate the thinner doors.

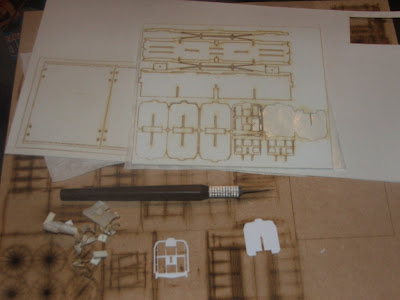

Anyway, the design of the ZH and ZG works on a central spine that slots into the floor and allows the formers and bulkheads to sit in slots to get the correct placement. The formers then support the doors which are a one piece wrap over the top.

The end bulkheads are then built up from 2 layers of 1mm styrene and attached....and this was where the first issue found.

Unfortunately we got rather major melt on the end bulkhead. I'm thinking of experimenting with either locating these bits well away from others on the sheet so they dont get knocked by residual heat, or even increasing the width of the lasered uprights by 0.1, or even 0.2. The underframe looks like it may have got knocked around as well, but I havent checked it yet. This pic shows the other bulkhead end removed ready for cleanup, and even it looks a tad manky (apologies for the blurry photo).

However, it was really the doors I was interested in. I had rastered in the fold lines, but was surprised to find they werent deep enough and had only really gone through the protective paper. Before unpeeling the second door (having discarded the first), I scored all the fold lines with the back of my scalpel blade a few times, and this did the trick. A wee bit of clever finger work turned out this:

Much more like it! A cleaner shape could probably be got with the use of bending bars or similar, but either way when attached to the formers it should hold its final shape quite nicely.

Unfortunately, I've got a few things to fix (sigh). The slots on the formers aren't deep enough (my fault for drawing one and copying, then not adjusting each former in turn for its individual position). I'll have to deal with the melt using the ideas previously aired, plus the measurements of the door circumference were slightly off on one of the planes and needs to be tweaked.

So yet again its back to the drawing board for the final tweaks, followed by another test assemble. So I cant really say when its due now, but at least its progress!

3 comments:

For areas that are prone to melt through, could a material like Phenolic sheeting or similar laminate be used? I have no idea how well it would cut with the Phaser, if it would cut cleanly at all. Choice of glue would also be a factor too. The the laminates are often quite rigid which could be beneficial for some pieces.

I'm impressed - that really looks good, can't wait to get some, thanks for all your effort and time...

cheers...

steve w.

no, I'm not 'kiding'

Good posting. Its an educational insite for modellers on the ongoing development needed to get another kit on the market. When asked by modellers about new kits, this is the time and effort needed to get it right before passing it onto the market.

Post a Comment